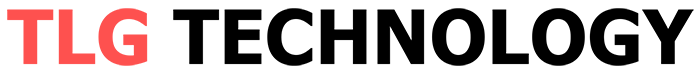

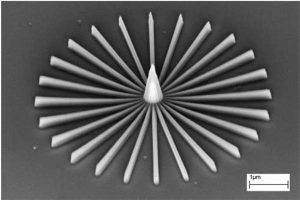

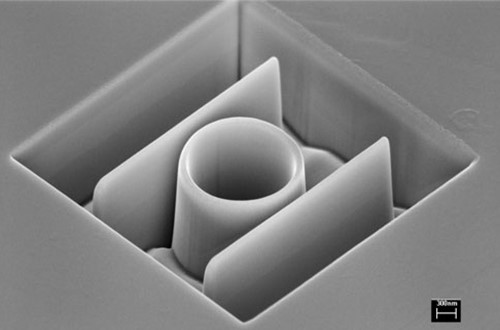

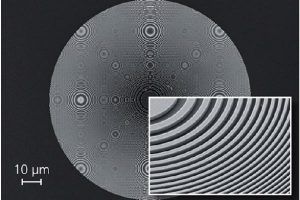

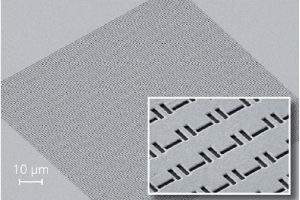

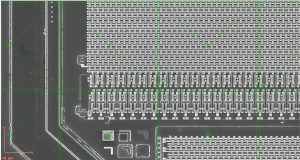

Raith is a leading technology manufacturer for electron beam lithography and focused ion beam nanofabrication instruments. In addition to this expertise in nanofabrication, Raith technology is employed for IC reverse engineering, IC layout reconstruction, and large area imaging in life sciences.

Be at the top of the game in your area of expertise, and choose the best Raith solution to realize your application!