EBPG Plus Features:

- Acceleration voltage 100kV and 50kV

- Overlay ≤ 5 nm

- Stitching ≤ 8 nm

- Maximum beam current 350 nA

- Full 8″ or 6″ exposure, 210 mm x 210 mm or 155 mm x 155 mm stage travel

- Automated 10-holder airlock

Highest Throughput

EBPG Plus has the unqiue combination of a powerful and stable beam with up to 350nA beam current and fully automated calibration and alignment prodcedures, ultrafast stage with short settlign times, advanced fracturing capabilities, and Firebirdmulti core pattern processor technology. Full 8: capability providing a pattterned area of up to 210mm x 210mm with waferscale pattern uniformity, a wide range of sample holders and the automated 10-holder loader

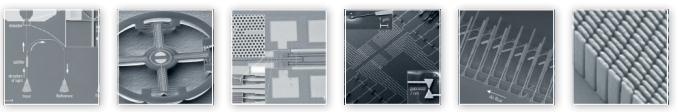

Leading In Application

The system tuning ensures perfect interaction between the various tool performance dimensions to deliver optimum nanolithography results.

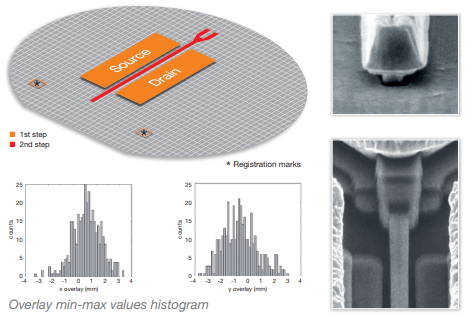

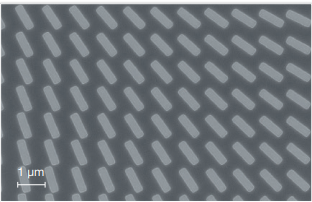

With excellent resolution and overlay better than 5nm, EBPG Plus has the highest-definition T-Gates for the ultra-fast high electron mobility transistors required for THz technology. The high-speed laser interferometer stage (up to 60 mm/s) ensures superior throughput for these sparse patterns.

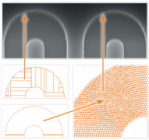

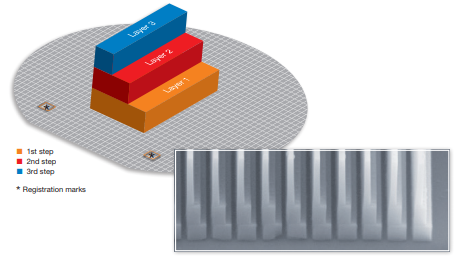

Large-area 3D stacked X-ray lenses consisting of nano-structures require three main prerequisites for good device performance.

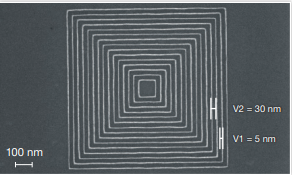

Ultra-high resolution, EBPG Plus provides excellent minimum linewidth quality down to 5 nm and below. The highly accurate focus and beam control, using automated height sensing, ensures linewidth homogeneity over the entire patterned area on wafer scale – even for large write fields.

5nm overlay for ultimate gate placement precision in HF devices

Test pattern with ultra-high resolution lines (5 nm) with 30 nm pitch. Pattern homogeneity is maintained over an entire wafer

Ultimate overlay, stitching and long term stability for large-area 3D stacked X-ray lenses

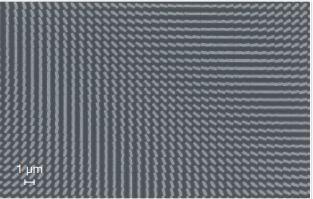

Metalens and large AR/VR gratings with Firebird and algorithmic pattern generation

EBPG Plus’s data processing solutions can handle a huge number of elements and achieve perfect fidelity for the perfect optical performance of metalenses. Algorithmic patterning technology supports the convenient generation of exposure data directly using proprietary shape elements and without conventional data files. Special fracturing features and Firebird helps to ensure ultimate pattern fidelity and a speedier process which result the TB-sized designs to be produced effortlessly.

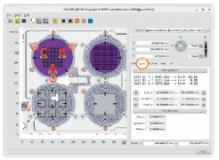

Facilitating workflows with smart hardware and software

Data preparation good data in – good and fast result out. Unique proprietary functions of the EBPG Plus are supported in GenISys BEAMER, including workflow automation right from the pattern design. Complex design and a new host of elementary shapes have been developed and can reach several 100GB that require smart data handling. Firebird is EBPG Plus new multicore pattern processor technology.

Automated wafer and multiple sample exposure. EBPG Plus provides a degree of automation where smart alignment and calibration routines are involved and multiple job exposures are automatically executed on the same or different sample/wafer mounted on multiple or separate sample holders.

Sample alignment made quick and easy. The new workflow allows the process to be reliable and improve efficiency with a new advanced confocal optical alignment microscope with motorized stage, separate screen, and digital connection to the EBPG Plus system to make the sample alignment convenient, fast and error-free.