Hakuto is the leading provider of ion beam etching system from small scale system

for R&D to mass production with over 50 years of experience.

Hakuto is the leading provider of ion beam etching system from small scale system

for R&D to mass production with over 50 years of experience.

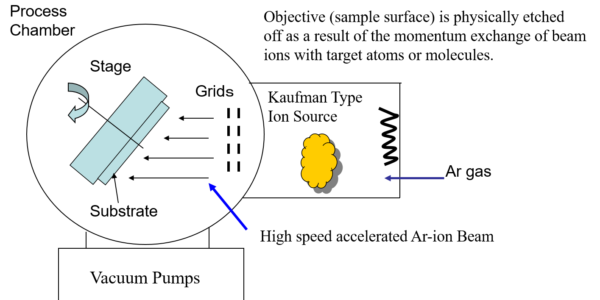

Ion Beam Etching (Milling) System

Ion Beam Etching (IBE) system is optimal etching technology for difficult-to etch materials such as Magnetic Materials, Gold, Platinum, Alloyed metals, and Compound semiconductor materials. IBE can be applied for materials which Reactive Ion Etching (RIE) cannot etch well.

IBE generates broad ion beam which strikes the substrate or wafer resulting in the removal of target materials.

Planetary movement of stage and wafer holder called “Dry Chuck Planet” achieve excellent etching uniformity. It also features manual/motorized ion beam incident angle adjustment.

φ4” Dry Chuck Planet holders on Planetary Stage

Stage Shutter for single stage

Shutter with a probe

to monitor ion current density

(Option)

Tilting stage with motor drive

Direct Cooling/Indirect Cooling Stage /Gas Cooling Stage

Direct cooling circulates cooling water inside wafer holder for excellent cooling performance.

Indirect cooling stage enables Dry Chuck Planet removable. It reduces the downtime caused by setting wafers on the wafer holders (Dry Chuck Planet) with Dry Chuck Fixture.

In addition, Backside Gas cooling stage is available.

Dry Chuck Fixture for wafer exchange

Flexibility

We response to customer’s specific requirement as much as possible in designing of system and offer

User friendly Touch panel screen interface

Customized Dry chuck planet holder

Specifications

Ion Source (GRID) Size: φ4cm, φ7.5cm, φ10cm

Stage: φ4″ Single Stage / Direct Cooling

Wafer Size: Up to φ4″

Etch Rate (nm/min) @ Si: > 10nm/min @ φ4cm IS

> 20nm/min @ φ7.5cm~ IS

Etch Uniformity (%): < ±6% @ φ60mm area @ φ4cm IS

< ±6% @ φ90mm area @ φ7.5cm~ IS

Wafer Temp (degree): < 100℃

Stage Angle: Manual

Specifications

Ion Source (GRID) Size: φ20cm

Stage : Pranetary (Rotation & Revolution)Stage

Direct/Indirect Cooling, Gas Cooling

Wafer Size: Up to φ8″

φ3″ x 8 wfs, φ4″ x 6 wfs, φ8″ x 1wf

Etch Rate (nm/min) @ Si: > 20nm/min

Etch Uniformity (%): < ±6% @ φ90mm area

Wafer Temp (degree): < 100℃

Stage Angle: Auto (Motor Drive)

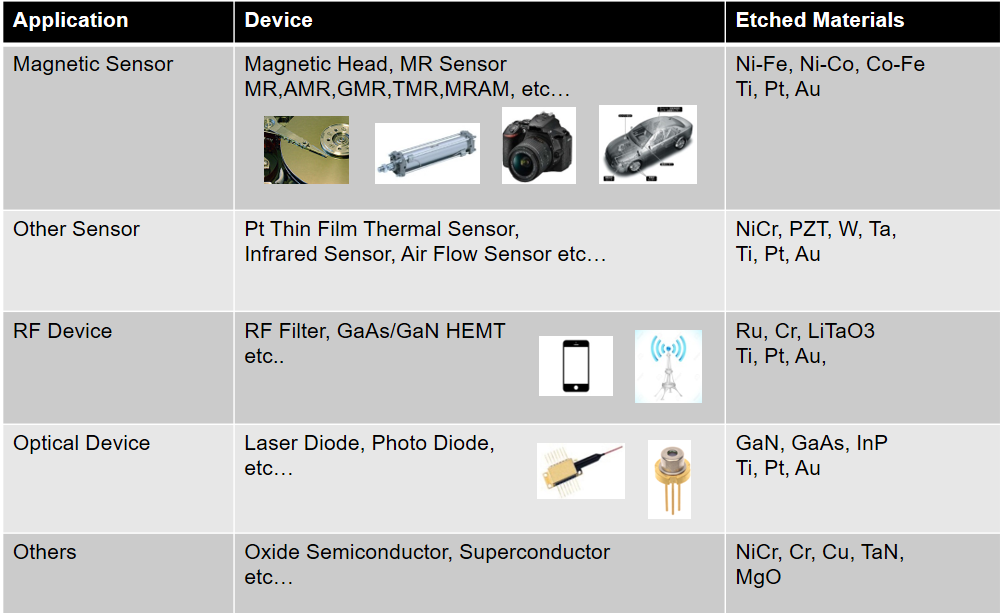

Application

Ion Source (GRID) Size: φ20cm

Stage: Pranetary (Rotation & Revolution)Stage

Direct/Indirect Cooling

Wafer Size: φ4″ x 12 wfs, φ5″ x 10wfr, φ6″ x 8 wfr

*option: large substrate

Etch Rate (nm/min) @ Si: > 20nm/min

Etch Uniformity (%): < ±6% @ φ90mm area

Wafer Temp (degree): < 100℃

Stage Angle: Auto (Motor Drive)

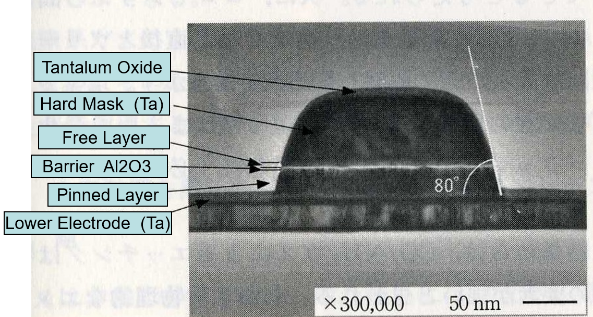

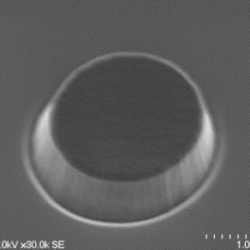

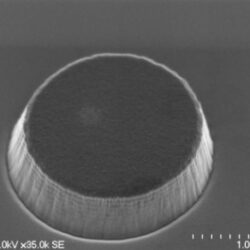

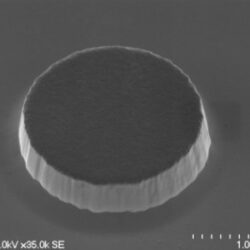

Cross sectional TEM image of

Multi Tunnel Junction (MTJ) etching profile

Cross sectional TEM image of

Multi Tunnel Junction (MTJ) etching profile

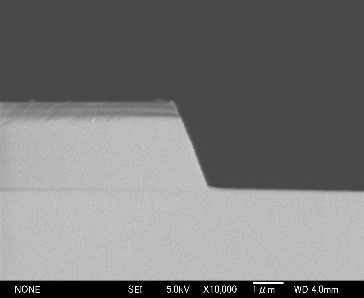

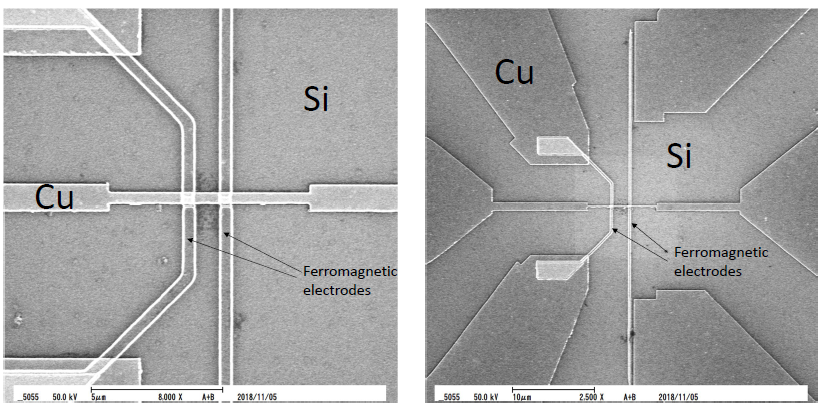

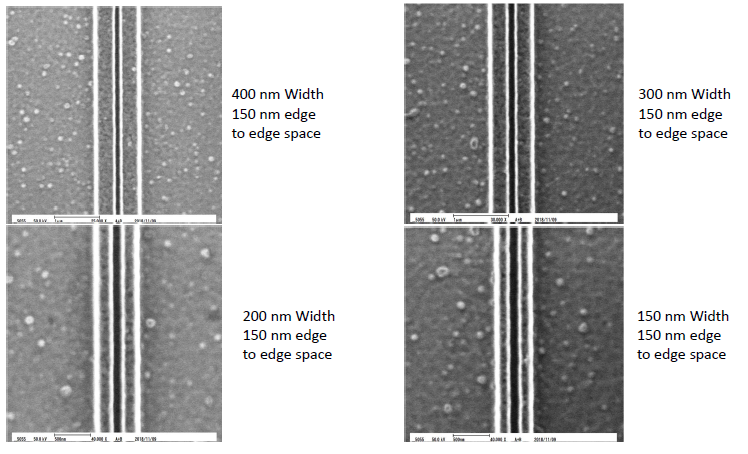

SEM images of ferromagnetic electrode by the ion beam etching